It’s not a new problem, but it’s one that is becoming more and more prevalent: foaming in aqueous bath-based cleaning.

Foam can be caused by a number of factors, including the basics: not getting the bath up to temperature before turning on the machine; pushing the bath past the soil load it can reasonably handle; equipment that needs to be cleaned; and so on.

But over the past few years, customers have been experiencing foaming problems that are not caused by these easy-to-remedy factors. Ironically, this trend is being driven by an overall effort to make the world a cleaner place: the sustainability movement, which has led to the introduction of both bio-based cleaners, such as Armakleen’s Bio24 aqueous solution, and “green” greases and oils. When these new chemistries interact with traditional petroleum-based surfactants, the potential for foaming is significantly increased.

Why Foam Is a Problem

Foam is a problem in the cleaning industry for a couple of key reasons. First, foam can escape a machine and turn a concrete floor into a slippery surface, creating a risk to workers’ health and safety. This foam also will not get recirculated into the machine via the sump, so cleaning power is reduced. In effect, whatever aqueous solution is turned into foam represents money poured onto the floor.

For many in the industry, the quick and easy solution has been to tip a defoaming agent into the sump. But this should be considered a temporary remedy; there is only so much defoamer one can add before it starts to lose its effectiveness. And when foam gets generated more quickly than a defoaming agent can break it up, the foam will begin to grow past its confinement area.

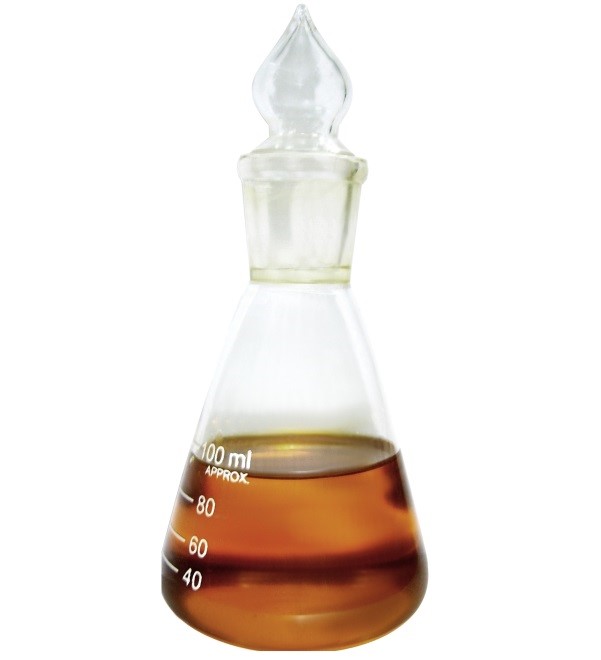

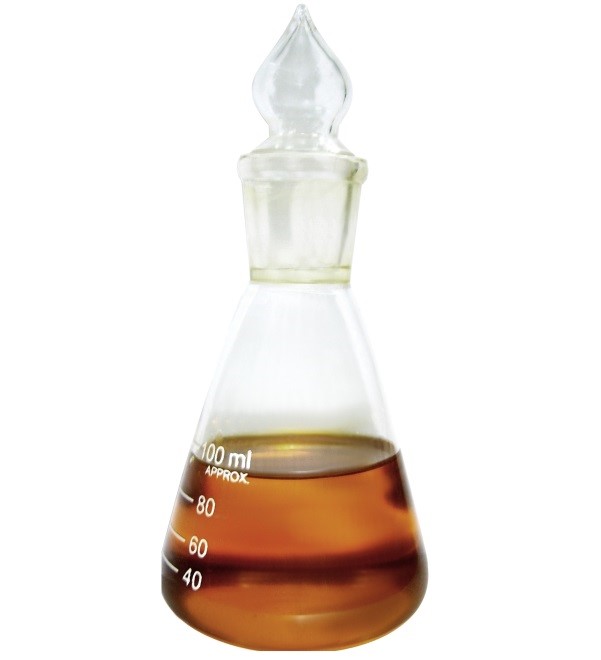

As the landscape has transformed toward increasing amounts of bio-based chemistries, the problem has grown. To better understand this, one might look more closely at renewable-sourced contaminants. Substances such as biodiesel are derived from animal fats or vegetable oils. These

break up when placed in an alkaline environment; essentially they turn into soaps, typically with high foaming potential. At the same time, the most effective type of environment for cleaning is an alkaline one. The issue is not confined to any particular type of soil or cleaner; although it will present itself more quickly for cleaning agents with higher pH values, any alkaline aqueous environment will eventually succumb to this problem.

Finding a Solution

Does this mean there’s no hope for aqueous cleaning? No. But a lasting solution won’t come from adding more defoamer — which, in fact, is already an ingredient in Armakleen cleaners. The solution may in fact lie with changing cleaning techniques altogether.

Does this mean there’s no hope for aqueous cleaning? No. But a lasting solution won’t come from adding more defoamer — which, in fact, is already an ingredient in Armakleen cleaners. The solution may in fact lie with changing cleaning techniques altogether.

At its most basic level, foaming is caused by aeration — the introduction of air into the system. Aeration is an essential component of spray washing as spray is formed by dispersion within air, so by its very nature spray washing contributes to foaming. Couple this with the industry changes to bio-based soils, and you’ve got a recipe for disaster. There are some specially-formulated cleaners available in the market such as ArmaKleen’s M-HP-2 that are designed specifically for high pressure spray applications; these can help control foam in many applications. But a

better solution may be to change over to a non-aerating process such as immersion agitation or ultrasonic cleaning. These types of systems eliminate and avoid issues caused by foaming, can help speed up cleaning times and even reach “hidden” areas in parts being cleaned. Only drawback is that, compared to spray washers, they can sometimes be more expensive and more complicated to understand.

Spray washing has long been considered a “go-to” technology for aqueous cleaning. Yet while a spray cabinet may represent a smaller investment up front, the savings realized may pale in comparison to the expense of intractable foam.

The Bottom Line

The growing problem of foaming in aqueous bath-based cleaning can only be solved by acknowledgment of the changing reality that has accompanied the sustainability movement. Defoaming agents may provide temporary relief, but an investment in non-aerating equipment alternatives may be the only way to ensure a lasting solution.

Armakleen, as a steward to the industrial cleaning marketplace, is committed to helping customers find solutions that will work — both for today and for the future. To learn more about the solutions Armakleen can provide, visit

http://www.safety-kleen.com or

http://armakleen.com.

Photos:

- Figure 1: The sustainability movement has produced substances like biodiesel, which contribute to the problem of foaming in aqueous baths. Source: Shizhao拍摄/CC BY-SA-3.0

- Figure 2: Spray washing cabinets (top) are an industry standard, but non-aerating technologies such as ultrasonic are a better solution for the problem of foaming. Source: Safety-Kleen Systems, Inc.

Does this mean there’s no hope for aqueous cleaning? No. But a lasting solution won’t come from adding more defoamer — which, in fact, is already an ingredient in Armakleen cleaners. The solution may in fact lie with changing cleaning techniques altogether.

Does this mean there’s no hope for aqueous cleaning? No. But a lasting solution won’t come from adding more defoamer — which, in fact, is already an ingredient in Armakleen cleaners. The solution may in fact lie with changing cleaning techniques altogether.