Cleaning Trial Summary

Customer Objective

The customer was looking to improve their cleaning performance, automate their cleaning process and reduce rework and reject rate.

Cleaning Trial Type

Temperature

Aqueous

Temperature

160⁰F

Industry

Time Required

Industry

Piping OEM Manufacturing

Time Required

1 minute

Segment

Substrate

Fabricated Metal Product

Stainless Steel

Soil

Cutting Fluids Drawing Lube Grease, Oil

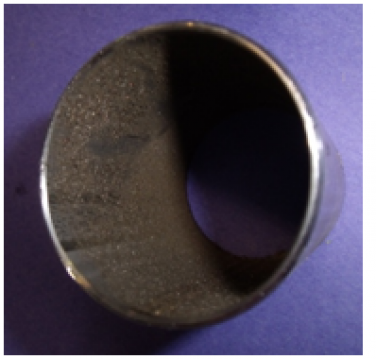

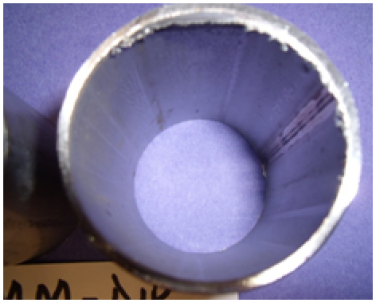

Description of Part(s)

Description of Part

Stainless steel pipe

Cleaner Used

5% by volume ARMAKLEEN™ 4 in 1 NF Cleaner

10% by volume ARMAKLEEN™ M-HP-2

Machine Used

Machine Used

- Agitating Immersion Washer (81.8)

- Spray Washer (TL3, FL250, FL500)

Post Cleaning

Post Cleaning

Fresh water rinse followed by air pressure drying.

Recommendation to Customer

Recommendation

The ArmaKleen Technical Center recommended the following;

- 5% by volume ArmaKleen™ 4 in 1 Cleaner In either an Agitating Immersion Washer or a Spray Washer at 160⁰F for a minimum of 1 minute.

- 10% by volume ArmaKleen™ MM-Dip in an Agitating Immersion Washer at 160⁰F for a minimum of 1 minute.

- 10% by volume ArmaKleen™ M-HP-2 in a Spray Washer at 160⁰F for a minimum of 1 minute.