Cleaning Trial Summary

Customer Objective

Improve cleaning performance, automate cleaning process, reduce rework and reject rate, reduce cleaning costs

Cleaning Trial Type

Temperature

Aqueous

Temperature

160°F, 160°F, 150°F

Industry

Time Required

Industry

Pulverizer Manufacturing

Time Required

2 hours

Segment

Substrate

Machine Manufacturing

Steel

Soil

, Oil

Description of Part(s)

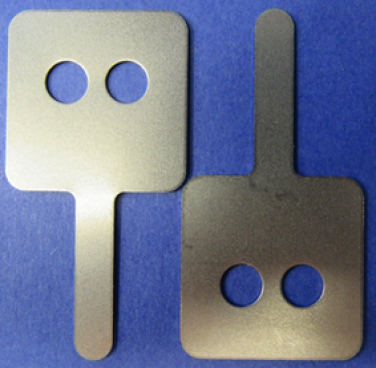

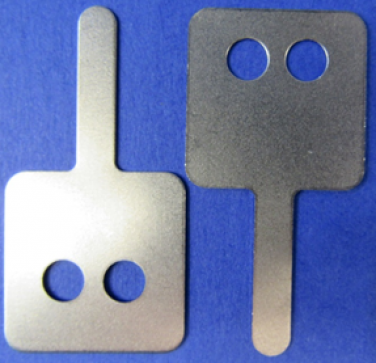

Description of Part

Assortment of male and female clips

Cleaner Used

5% by volume ArmaKleen™ Bio 24

Machine Used

Machine Used

- Spray Washer (JRI FL 250, JRI FL 500, JRI TL 3)

- Ultrasonic Washer (SK Blackstone 6315)

- Spray Under Immersion washer (Graymills T12, Graymills T24, SK Model 81.8 w/ SUI)

Post Cleaning

Post Cleaning

Fresh water rinse and air pressure dried, followed by further drying in an incubator at 220°F

Recommendation to Customer

Recommendation

The ArmaKleen Technical Center recommends using a 5% by volume solution of ArmaKleen™ Bio 24 at 150°F in a Spray-Under Immersion Washer for a minimum of 30 minutes to 2 hours or a 5% by volume solution of ArmaKleen™ Bio 24 at 160°F in a Spray Washer or an Ultrasonic Washer for a minimum of 30 minutes to 2 hours