Cleaning Trial Summary

Customer Objective

Improve cleaning performance, automate cleaning process, reduce rework and reject rate, reduce cleaning costs, reduces VOCs, eliminate hazardous chemicals/waste

Cleaning Trial Type

Temperature

Aqueous

Temperature

160°F

Industry

Time Required

Industry

Road Supplies Manufacturing

Time Required

4 hours

Segment

Substrate

Wholesale Trade

Brass

Copper

Soil

Adhesive Baked on Carbon Cutting Fluids Drawing Lube Glue Grime, Oil

Description of Part(s)

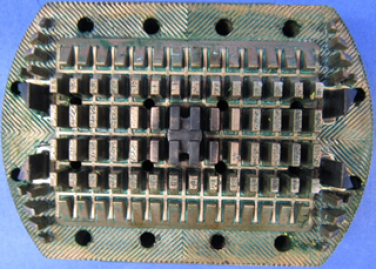

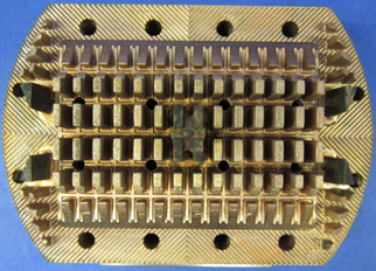

Description of Part

Dies with inserts

Cleaner Used

10% by volume M-100 BCR (Baked on Carbon Remover)

Machine Used

Machine Used

- Spray Under Immersion Washer (Graymills T12, Graymills T24, SK Model 81.8 w/ SUI)

- Ultrasonic Washer (SK Blackstone 6315)

Post Cleaning

Post Cleaning

Fresh water rinse and air pressure drying

Recommendation to Customer

Recommendation

The ArmaKleen Technical Center recommends using a 10% by volume solution of ArmaKleen™ M-100 BCR at 160°F in a Spray-Under Immersion Washer for a minimum of 4+ hours