Cleaning Trial Summary

Customer Objective

The customer was looking to improve their cleaning performance, automate their cleaning process, reduce their cleaning costs and eliminate hazardous chemicals and waste.

Cleaning Trial Type

Temperature

Ink

Temperature

150°F – 160°F

Industry

Time Required

Industry

Medical Manufacturing

Time Required

4 hours

Segment

Substrate

Machine Manufacturing

Aluminum

Rubber

Stainless Steel

Steel

Soil

PMS Black Ink with Silicone, PMS Black ink without Silicone

Description of Part(s)

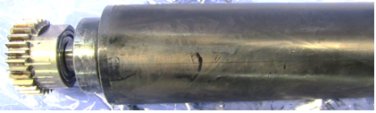

Description of Part

Print roller and print housing unit

Cleaner Used

100% by volume ARMAKLEEN™ Paint & Ink Remover

Machine Used

Machine Used

1. Spray Washer (JRI FL250, JRI FL500, JRI TL-3, Better Engineering G-2000)

2. Spray Under Immersion Washer (Graymills T12, Graymills T24, SK 81.8 w/SUI)

Post Cleaning

Post Cleaning

Fresh water rinse followed by air pressure drying.

Recommendation to Customer

Recommendation

The ArmaKleen Technical Center recommended using 100% by volume ArmaKleen™ Paint and Ink Remover at 160°F in a Spray Washer or in a Spray Under Immersion Washer for a minimum of 4+ hours.