Cleaning Trial Summary

Customer Objective

The customer was looking to eliminate hazardous chemicals and waste and reduce VOCs.

Cleaning Trial Type

Temperature

Polymer

Temperature

160⁰F in the Spray Washer, 150⁰F in the Agitating Immersion Washer

Industry

Time Required

Industry

Polymer coating manufacture

Time Required

8 hours

Segment

Substrate

Non-metal Manufacturing

Plastic

Stainless Steel

Soil

Bosc24T Cab-O-Sil TS-720 CYASTAT 609 Methylhydrogenpolysiloxane PanTINT, Skybon ES-120

Description of Part(s)

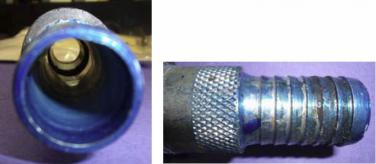

Description of Part

Plastic clamp, stainless steel cup, stainless steel cap and stainless steel pipe connectors

Cleaner Used

100% by volume ARMAKLEEN™ Paint & Ink Remover

Machine Used

Machine Used

- Ultrasonic Washer (SK6315 Blackstone model 3523)

- Agitating Immersion Washer (81.8, T12, T24)

- Spray Washer (TL3, FL250, FL500)

- Spray Under Immersion Washer (T12, T24, 40.1, 81.8 w/SUI)

Post Cleaning

Post Cleaning

Fresh water rinse followed by air pressure drying.

Recommendation to Customer

Recommendation

The ArmaKleen Technical Center recommended using 100% by volume ArmaKleen™ Paint and Ink remover at 160⁰F in an Ultrasonic Washer or a Spray Under Immersion Washer for a minimum of 8 hours.