Cleaning Trial Summary

Customer Objective

The customer was looking to improve their cleaning performance, reduce their cleaning costs, eliminate hazardous waste and chemicals and reduce VOC’s.

Cleaning Trial Type

Temperature

Ink

Temperature

160⁰F

Industry

Time Required

Industry

Screen printing

Time Required

1.5 hours

Segment

Substrate

Fabricated Metal Product

Aluminum

Ceramic

Steel

Soil

, Screen ink

Description of Part(s)

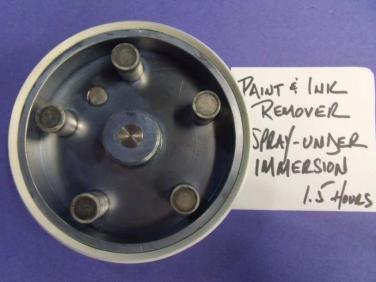

Description of Part

5” diameter steel, aluminum and ceramic dishes

Cleaner Used

100% by volume ARMAKLEEN™ Paint & Ink Remover

Machine Used

Machine Used

- Spray Under Immersion (T12, T24, 40.1, 81.8 w/ SUI)

- Spray Washer (TL3, FL250, FL500)

Post Cleaning

Post Cleaning

Light brushing with a nylon bristle brush during fresh water rinsing followed by air pressure drying.

Recommendation to Customer

Recommendation

The ArmaKleen Technical Center recommended using 100% by volume ArmaKleen™ Paint and Ink Remover at 160⁰F in a Spray Under Immersion Washer or a Spray Washer for a minimum of 1.5 hours.