Cleaning Trial Summary

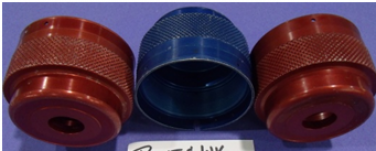

The customer was looking to improve their cleaning process, automate their cleaning process, reduce rework and reject rate, clean mixed metals together, reduce their cleaning costs, eliminate hazardous chemicals and waste and reduce their VOC’s.

100% by volume ARMAKLEEN™ Paint & Ink Remover

20 % by volume ARMAKLEEN™ Rust Remover

Spray –Under-Immersion Washer (T12, T24, 40.1, 81.8 w/ SUI)

Spray Washer (TL3, FL250, FL500)

Agitating Immersion Washer (81.8, T12, T24)

For the label and adhesive removal the parts were lightly brushed with a nylon brush during fresh water rinsing followed by air pressure drying. For the rust removal, the parts were fresh water rinsed and air pressure dried.

The ArmaKleen Technical Center recommended using 100% by volume ArmaKleen™ Paint and Ink Remover at 160⁰F in a Spray Under Immersion Washer for a minimum of 2 hours for the removal of glue/adhesive. The ArmaKleen Technical Center recommended using 20% by volume ArmaKleen™ Rust Remover at 160⁰F in a Spray Under Immersion Washer for a minimum of 30 minutes for the removal of rust.